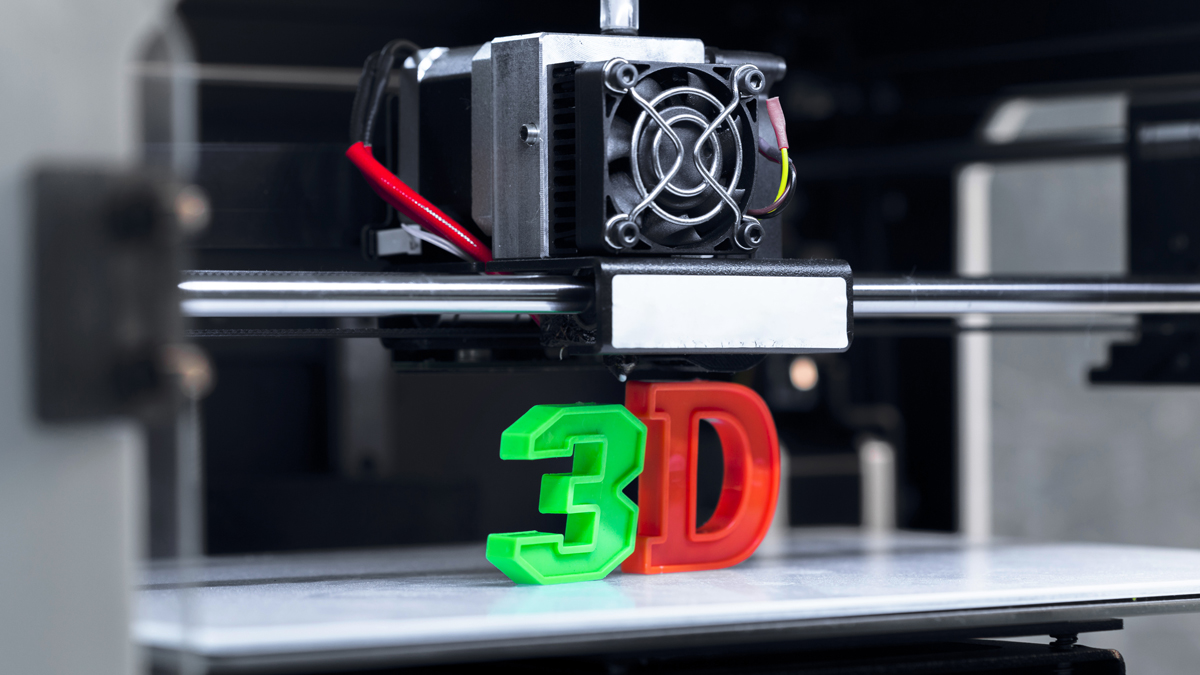

There are many variables that factor into the costs of 3D printing. These will range depending on the hardware you are using, the materials, the programs, and designs, or if you decide to outsource all the work. Here are a few factors to consider to help you determine how much it costs to get something 3D printed.

Size

One of the bigger factors that will make a difference is the costs it takes to get something printed in the size of the item that you want to print. Obviously, the greater the size that you need to print an object, the more material you will need to use. This will translate to an increase in your cost. Additionally, if you are hiring a printing company or outsourcing your job, a bigger job will also require more time to create and complete your projects. If you are printing yourself, you have to consider the time it takes to complete your job as less time means more products, which translates to funds and income. The size of your 3D print plays a significant role in the final costs.

Material

Another aspect that you have to consider when you are 3D printing is the material costs of your items. The prices will fluctuate and vary depending on manufacturing costs. If you choose to go with cheaper material, the quality of your prints will suffer. Choosing more expensive resin will of course come with a higher price tag, but the quality of your prints will be significantly more. This is especially important when you consider that some models are more complex and intricate than others. When you take the time to click here, you’ll see a more in-depth analysis of the pricing breakdowns of material associated with 3D printing costs. If you are 3D printing your items on your own time, you can offset the cost by buying in bulk, but that assumes you will be putting all that resin to use. If you are going to a 3D printing company for your needs, their prices will be relatively lower than your costs, as their cost of resin will be significantly lower than yours with their bulk sales contributing to corporate discounts.

Finish

In addition to material, you also want to consider any sort of finish, paints, or added aesthetic touches as further costs. You have to consider this because as you print materials and objects, they will have a generic design. Depending on what it is you are printing, you will want it painted, or coated to serve different purposes. You might need to match colors with other parts it connects with if you are printing components of a larger system, or just need it to have a certain visual look if it is something like a costume, figurine, or decoration. Depending on the visual need, it will cost you different prices.

Complexity Of The Design And Strength Of Structure

The size is not the only physical aspect of your 3D printed design that you have to consider impacting the cost of your model. In addition to the size, the complexity and structure will also influence the costs. Just because you can think of something to print does not mean that it will really hold together or work in 3D space. You have to incorporate ideas of structural engineering to ensure that your designs are durable and can stand on their own. If you are printing something that has different components that interlock with each other, those components will need exact measurements and have to have the proper design to ensure that you are getting exactly what you want. If you do not take the time to properly research, study, measure, and plan your designs, you will be paying a lot more money to have to redesign and reprint your models.

Machine And Manpower

If you are buying your 3D printed items from a company or person that has access to a printer, you will also factor in the cost for their time. This will vary between each company or person doing the printing, as they will attribute their services with prices different. They may be working with other people and this would make their time much more valuable. If you are printing on your own, you have to factor in your initial costs like the printer, as well as your hardware and software to be able to print your models and objects.

Your models will have different costs depending on your needs and wants of your project. There are costs to consider whether you are doing the project yourself, or getting help from a company that can provide the materials and services for you. It is important that you factor all these into understanding how much you invest in your 3D printing.